Innovation Equipment Services exists to provide its clients with

a unique level of problem solving,

specialized skill sets and knowledge combined across numerous industries,

and a firmly understood responsibility to deliver.

PRECISION MANUFACTURING

Physical solutions are achieved responsively through a deep understanding of materials and advanced fabrication and machining.

Engineered solutions meet precise dimensional requirements.

Examples

1. Linear Accelerator Precise Pit Frame and Electrical Raceway

- Direct oversight of construction crews over numerous successful installations combined with iterative engineering has resulted in a dimensionally superior pit frame product that can be quickly, easily, and accurately assembled and adjusted in the field.

- Pre-engineered quick-install kits accommodate a wide range of installations and have been progressively designed from installer feedback.

- With facility retrofits, uncertainties are inevitable. For this reason, readily available tools can be used by installers to adjust the kit according to newly-acquired field measurements.

- Each corner is independently adjustable even after positioning of the frame. Once the orientation of the pit frame has been measured and verified, the orientation can be securely locked in place.

2. Laser Etched Thermometer Covers for Use at Cold Storage Facilities

- Materials were selected to withstand both harsh and corrosive environments.

- Sourcing and managing the right manufacturing resources enabled delivery of robust products with crisp and premium quality finishes.

INDUSTRIAL EQUIPMENT

Components are designed to withstand the realities of 24/7/365 industrial production.

Examples

1. Carriages for Gantry Chain Hoist Application

-

The equipment was designed to last in a heavy-duty industrial production environment.

-

Close oversight of manufacturing processes ensured the timely delivery of quality products.

-

Engineering support was provided for installations of both the mechanical carriage and the chain hoist.

MACHINE COMMISSIONING

Greenfield equipment is brought to life and brownfield equipment is revitalized.

Examples

1. Fume Extraction Control System

-

Electrical control panels were designed per stringent client specifications.

-

The system runs 24/7 and automatically performs a daily functional test to ensure the equipment is always operational and ready.

-

Engineering support during installation, power-on, and startup ensured a smooth commissioning process.

-

Our understanding of the critical needs for both production and maintenance teams informed the design of a customer-requested training program. Multiple shifts of each team benefited from an approachable and hands-on training experience.

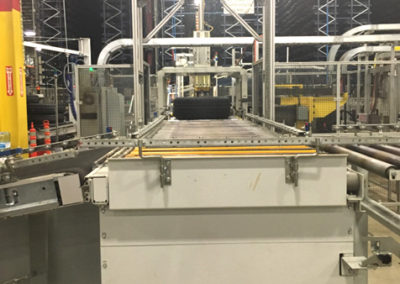

2. Upfit of Automated Conveyor System

-

Planning, commissioning, and testing was coordinated between multiple stakeholders on behalf of an automotive supplier of wheel and tire assemblies.

-

An existing conveyor system was upfitted and reprogrammed to optimize system functionality and accommodate the addition of a new production quality process.

-

The project was performed under a strict timeframe and dedicated production support was provided. This dedicated support provided the supplier peace of mind during subsequent startup as well as afforded them the opportunity to efficiently optimize their process.